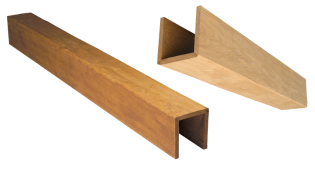

Oak beam covers, also known as beam casings, are designed to conceal unattractive structures like RSJs (steel joists) concrete lintels, or pipework with a beautiful and solid-in-appearance oak structure. These authentic oak beam covers or oak RSJ covers, are handcrafted using solid, kiln-dried oak. You can choose between two-sided, L-shap covers, three-sided, U-shape covers, or four-sided, O-shape covers.

We also provide end capping options for exposed ends of oak beam casings. Each cover is hand-finished with our trademark hand-wrought finish, to make the oak beam covers and oak RSJ covers indistinguishable from solid oak beams.

Using selected kiln-dried timber, with small knots and splits, oak beam covers can work either as a distinctive, handcrafted standalone feature or be made to integrate with other oak components in your property.

At Oakmasters, we take pride in our skilled craftsmanship. Every oak beam cover is hand-made exactly to your specifications. Our craftsmen construct every oak beam casing by hand, using a unique jointing technique to conceal connections between individual oak beam cover sections. The result is an oak beam cover that is indistinguishable from solid oak beams.

Oakmasters’ oak beam covers are made to measure for your specific project. Unlike pre-molded options, our bespoke designs accommodate quirks like uneven lengths, tapered ends, and unusual openings for a seamless cover installation. Compatible with solid oak beams, our beam covers seamlessly blend RSJs with oak beam covers and solid oak joists, replicating the appearance of authentic oak beams. For extra-long beams exceeding 9 meters, two casings can be joined lengthwise using a handcrafted iron strap by our local blacksmith.

Our oak beam covers are supplied to you, and ready to be installed by your chosen builder. The installation process is straightforward and can easily handled by your local contractor. If your project is more complicated, or your contractor needs specialist advice or help, then we are happy to discuss your options.

To get started with your oak beam cover, simply follow these steps, and we will then be able to offer you a price estimate.

Begin by measuring the dimensions of the area you intend to cover. Provide us with the width, depth, and length of the structure you wish to conceal. Don't worry about adding extra allowances; we will handle those details for you.

Let us know about the structure you want to disguise, whether it's vertical or horizontal. This helps us determine if you need a two-sided, three-sided, or four-sided beam cover. If your project includes unique requirements like cutouts, carried side lengths, or end caps, please us know.

Oak beam covers require special handling due to their fragile nature. Organising safe transport is therefore essential, and knowing the delivery details in advance can impact the overall cost, so please remember to provide your delivery address for a price estimate.

Take a look at our price guide to see example costs for two-sided, three-sided and four-sided casings and the additional features available.

Featuring an L-shape profile, this two-sided oak beam cover can be used for both vertical and horizontal settings. Made with precision, each oak beam cover is tailor-made to fit your project. Whether it's RSJs, concrete lintels, or pipework, our two-sided oak beam covers deliver an authentic oak appearance.

Our three-sided oak beam covers come designed with a U-shape profile. These covers wrap around your structures, combining aesthetics and functionality seamlessly.

Featuring an O-shape profile, the four-sided oak beam covers envelop your structural elements entirely. Each piece of cosmetic cladding is designed for easy installation, made with precision using our state-of-the-art CNC machine.

We'd love to hear about your oak framed project. Call us today on +44 (0) 1444 455 455 +44 (0) 1444 455 455 for a no obligation estimate. Alternatively, complete the form below and we will be in touch.

Will oak beam covers shrink or crack once fitted?

Our oak beam covers are crafted from kiln dried oak, the same quality of oak used for furniture making. The joints are glued and then surface treated to make sure they are almost invisible. You can fit our oak beam cover confidently and plaster around them without worrying about gaps appearing between the oak beam casing and the plaster or indeed the oak beam casing twisting or cracking.

Is an oak beam cover cheaper than a solid oak beam?

Kiln dried oak is more expensive that green oak per cubic metre due to the amount of processing and storage required to produce the planks. In addition, you need to consider that it takes a lot of skill to craft an oak beam casing and it takes a considerable amount of time to make it. It’s a little bit like cabinet making. Therefore oak beam covers are not cheaper than solid oak beams.

Could you supply hollowed out oak beams made from green or air-dried oak?

Hollowing out green or air dried oak beams would be an extremely laborious process. So not only would the cost of it include the cost of the oak that was thrown away from the middle, but it would also include hours of labour that would go into producing a hollowed out oak beam by hand. In addition, both green and air dried oak continue to shrink and crack once fitted, which would be further accentuated by the fact that the walls are now thinner, making the hollowed out oak beam more prone to twisting and warping. This has the potential to cause you a lot of headache in the future.

The terms fake oak beams or false oak beams would suggest that the oak beam covers are made from veneered MDF or other materials, such as polymer and resin compounds. There are indeed fake oak beams moulded from polymer and resin available on the market. However, Oakmasters’ oak beam casings are hand crafted from solid oak.